A question of part dimensions …

C 50 U | Kusters Precision Parts | Metal Products

With 5-axis machining know-how, mutually complementary machine working areas and an elevated level of automation, perpetually facing stiff competition and on the path to success.

"Experts in precision parts" for more than 40 years with this philosophy – and the range of machining technologies associated with it, as well as assembly-related services – Kusters Precision Parts with headquarters in Oss, Netherlands is one service provider that is more in demand now than ever, having developed over the years from the conventional extended workbench to manufacturing technology partner. Change of scene: A good 10 years ago a user report on the forward-looking topic "New dimensions in 5-axis milling" examined the company, then operating under the name Kusters Metaalbewerking Oss bv. Even then the son of the company founder and current Managing Director, Jan Kusters, reported that he would also be building on the competence and knowhow of long-time machine supplier Berthold Hermle AG from Gosheim D-78559 in 5-axis technology. Consequentially the machine park, which comprised only 17 CNC milling and turning centres in 2003/2004, already counted 11 from Hermle. That included CNC universal milling machines and especially the innovative C series CNC machining centres from Hermle for economical and highly accurate 4- and 5-axis machining. When the new C 40 U 5-axis high-performance machining centre was introduced in fall 2002, Jan Kusters and his colleagues saw "that the time had come for a whole new dimension of milling" as they phrased it then, and became involved in the technology with that same C 40 U 5-axis high-performance machining centre. This acquisition proved to be a decisive step for the future success of the company. Kusters Precisions Parts has developed continuously over the past 10 years, with 40 skilled employees now compared to 25 then, working today with 20 Hermle machining centres compared to 11 earlier, and offering today's customer a range of manufacturing technologies that includes milling, turning and electrical discharge machining as well as grinding, supplemented by measurement technology and assembly.

-

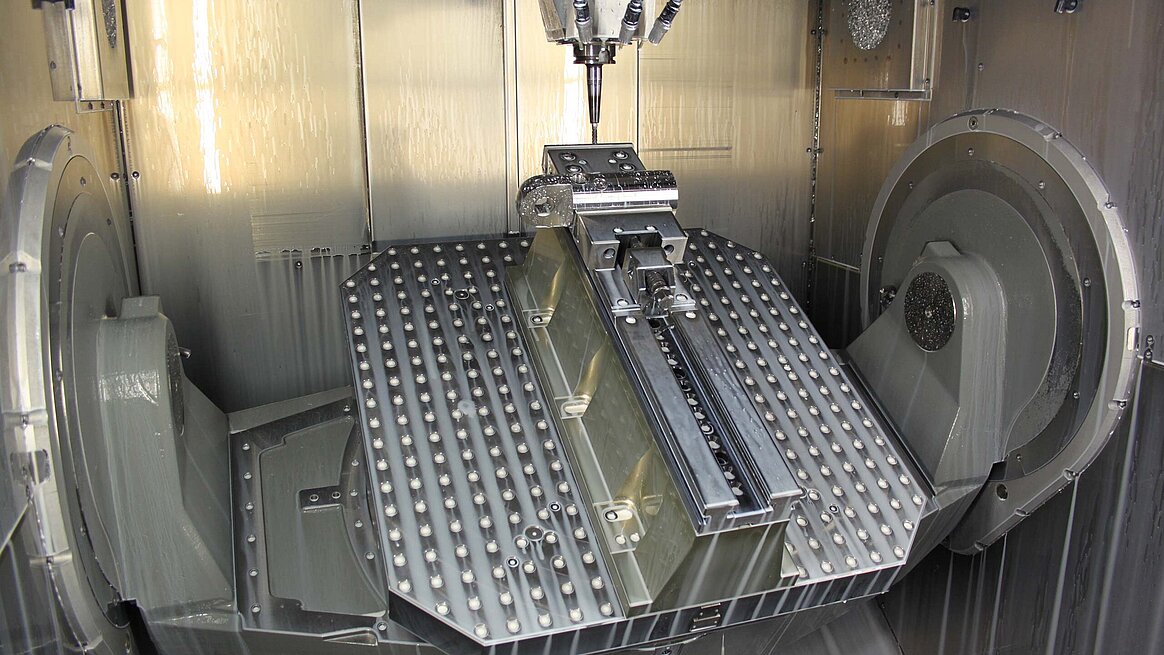

The large working area (1000 x 1100 x 700 mm, X/Y/Z) of the 5-axis machining centre's C 50 UP and the NC rotary table 700 mm in diameter for pallets 800 x 800 mm to hold workpieces weighing up to 2000 kg -

The new highly automated compact milling system with the 5-axis high-performance machining centre C 22 UP and pallet changer PW 150

New dimensions or: "Shoebox-sized" workpieces were yesterday …

Milling takes up the main part, literally in all dimensions. While Kusters concentrated earlier on workpieces no larger than shoebox size (J.Kusters, quoted in 2004), component dimensions up to roughly 1000 x 1100 x 700 mm pose no special challenges today. This is evident from the current machine park, which has not only been modernised and expanded again and again in the last 10 years, but has also grown in terms of working ranges and hence workpiece dimensions. The same can be said of the level of automation in single-part, small and medium series production. Jan Kusters has always been very aware that he must offer his customers the latest technologies and good prices as well, because he wants to continue to do well in business in the future. Jan Kusters explains: "Our customers demand reproducible precision from us as well as on-time delivery plus creative and above all economical solutions, and finally capacity to manufacture individual parts quickly and for JIT-oriented batch manufacturing. Requirements have risen steeply, not least due to the enormous functional integration in mechatronics, which results in much more complex workpieces, and also due to the trend towards tools that are integrated into the functionality, which require high levels of complexity and accuracy now in the µ range. That applies equally to small and large parts, and we have therefore aligned our machine park to 5-axis/5-sided/complete/ simultaneous machining based on Hermle machines."

This was the goal: To produce 168 hours a week in manned and unmanned operation

The latest acquisitions in the machine park of Kusters Precision Parts, pointing the way to things to come, are two Hermle machining centres for large parts type C 50 U and C 50 UP respectively and also a Hermle 5-axis high-performance machining centre type C 22 UP designed for small and medium-size workpieces. While the C 50 U 5-axis high-performance machining centre is designed as a standalone system for universal/flexible and manned machining of large format workpieces, the second C 50 UP 5-axis high-performance machining centre is equipped for lightly manned operation with a pallet changer. The same applies to the smaller C 22 UP 5-axis machining centre, which has a type PW 150 pallet changer with 11 pallet spaces. The C 22 UP 5-axis high-performance machining centre features compact dimensions and a spacious working area measuring 450 x 600 x 330 mm (X/Y/Z). It holds 65 tools in the integrated tool magazine and another 87 tools in the additional magazine and has a swivelling rotary table with a diameter of 320 mm. The C 50 U and C 50 UP 5-axis machining centres feature working areas measuring 1000 x 1100 x 700 mm (X/Y/Z). They hold up to 60 tools in the tool magazine and another 41 each in the additional magazine and are equipped with swivelling rotary tables 700 mm in diameter for pallets 800 x 800 mm. Together with working ranges of the Hermle machining centres mentioned above, Kusters Precision Parts now covers workpiece dimensions from a few millimetres to almost 1 m³. This gives them great flexibility in responding to all imaginable customer requirements. Jan Kusters believes his change of strategy has been absolutely confirmed and notes in conclusion: "Our main strengths earlier were in prototype and single part manufacturing. Thanks to the higher level of automation, today we have that same strength in 5-axis machining and workpiece handling, as well as small and medium-sized series manufacturing. With the possibility pf working economically and with short throughput times, highly flexibly with stand-alone machines and automated milling systems at µ accuracy, we offer many advantages for our customers, of which a good 25% come from Germany, by the way, which we can better server with expanded capacities. With the Hermle machines we have relied on for 25 years now, we are able to machine almost everything to customer specification and also substitute conventional technologies now and again, for example replacing electrical discharge machining with 5-axis milling, or carbide milling with coordinate grinding, thereby achieving further cost optimisation."