Night shift on its own

The robot loads all sorts of components onto the swivelling rotary tables of the 5-axis machining centres: made from plastic, aluminised steel, cast materials and in unit numbers from 1 to 500. "The Hermle machines handle challenges such as accuracy and material complexity with ease – including the reliable removal of the various chips and shavings", confirms Bulander. As a result, the production cell also runs overnight and at the weekend – without supervision. "Why should the machine be idle at night? Surely, it’s better to have it earning money while we sleep". His argument proves to be correct in practice. "To date, we have never had a crash during an unmanned automation process. Naturally, that’s also down to the fact that our employees just know what they are doing", acknowledges the managing director.

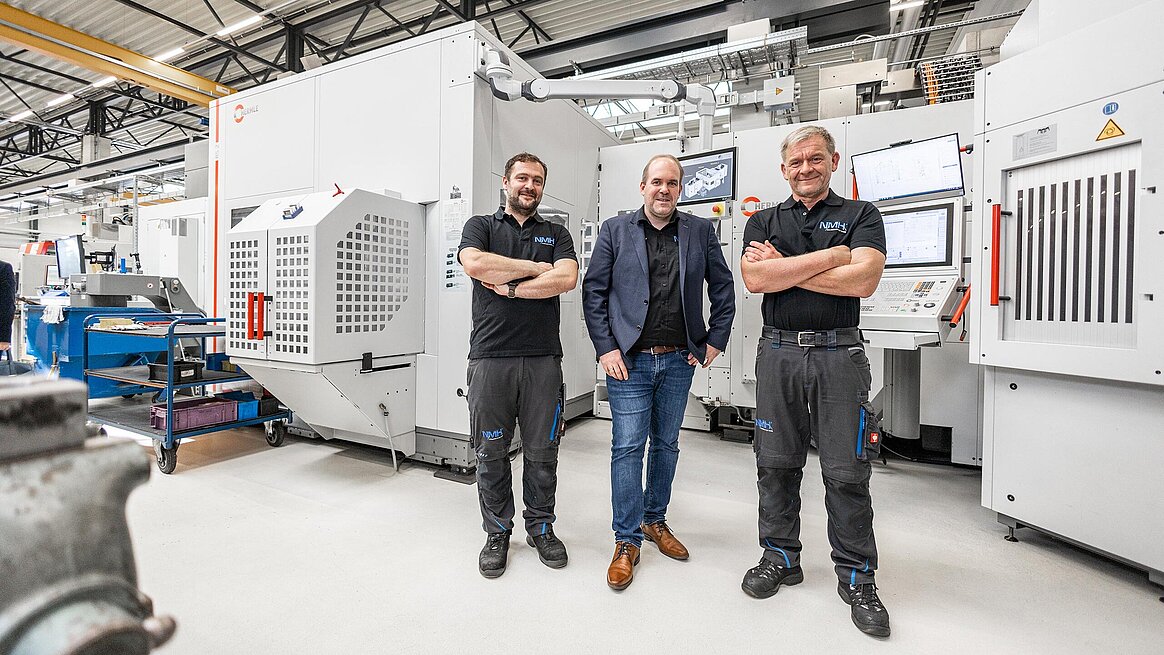

A glance at the swivelling control panel on the RS 2 system reveals another unusual feature: a second screen with a web cam is mounted above the Hermle monitor. That’s because NMH embraces paperless production and has developed its own production software called COCO (ControlCockpit) for the purpose. This allows NMH to track and manage all manufacturing processes in real time – also with the help of cameras installed in the machining areas of the C 42 U. This means that workers can keep an eye on the process at all times even if they are not standing beside the machine. Every component and every production series is accompanied by a small white digital tag that is centrally managed and labelled by NMH. The QR code that is then generated ensures that all important data, be it the tools to be used, CAD drawings or measurement logs, is available in the latest version at any time and from any workstation.

This digital transparency also plays a key role in enabling Bulander to meet the expectations of his customers by combining on-time delivery with quality at an attractive price. The Hermle machining cells are another secret to his success. "I believe we chose the right time to invest in a system that ensures our competitiveness and provides us with reliable and precise results", says the managing director in summary. He is equally satisfied with the cooperation with Hermle, which he describes as "extremely punctual, competent and always very professional". However, he is happiest when he hears nothing from the service department: "That means everything is running smoothly. That’s the ideal scenario for both sides".