C 40 U | Additive manufacturing | Julius Blum GmbH | Furniture construction

Blum is a company with worldwide operations specialising in the manufacture and sale of furniture fittings. The main product groups are lift, hinge and pull-out systems for furniture, primarily in kitchens. Founded in 1952 by Julius Blum, the company is a market leader in the furniture fittings industry today. With just under 6400 employees and annual sales (July 2013 to June 2014) of more than 1.4 billion euros, exports account for 97% of all business. Blum is a fully family-owned company, as it always has been, and is deeply bound to local traditions, producing consistently in seven plants in the Austrian state of Vorarlberg and in additional plants in Poland, USA and Brazil. Supported by 27 subsidiary organisations and representatives, the Blum Group regularly delivers products to customer in over 120 countries around the world. The Vorarlberg location with 7 plants plays a leading role: Company headquarters and administration are based there, as are research and development, design, tool and special machine manufacturing, apprentice training and production. Blum's innovation contributes very fundamentally to the success of the company, as underscored by the fact that Blum has been one of the most diligent patent applicants in Austria over the years, currently holding more than 1200 protected rights. Many of the inventions are considered benchmarks even today, setting standards worldwide for hinge, lift and pull-out systems. To be able to meet the demands of its customers plus the very high delivery and quality standards it has set for itself, Blum relies on a high level of internal manufacturing, including all equipment, tools and special machines required for production.

A partnership build on the awareness of both partners' strengths

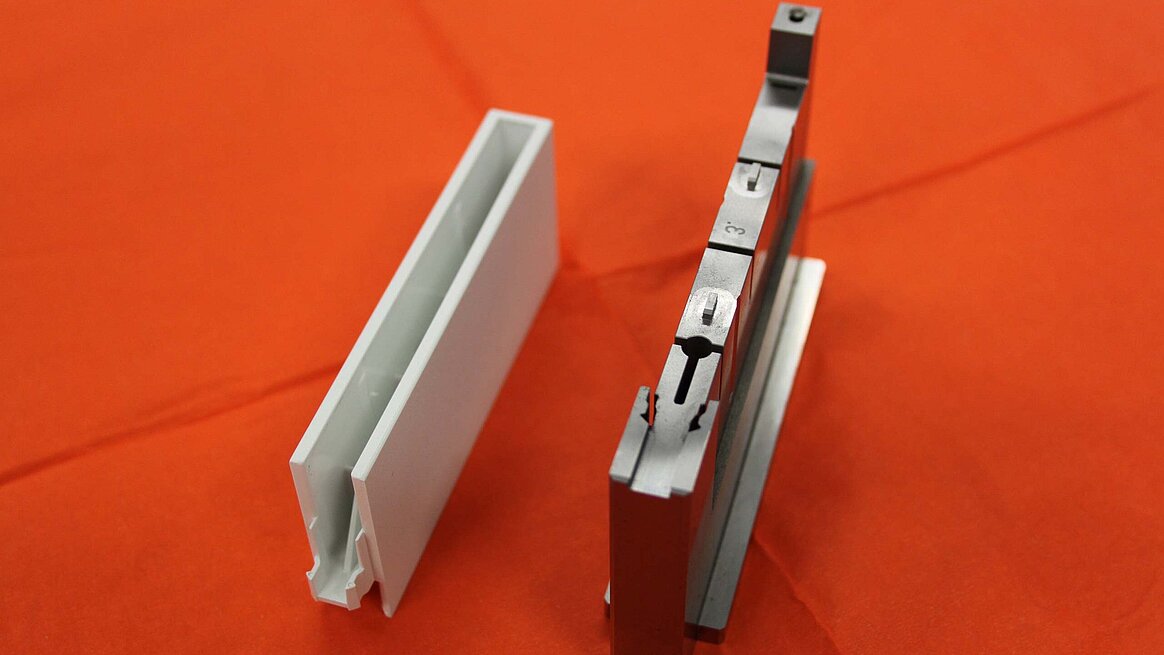

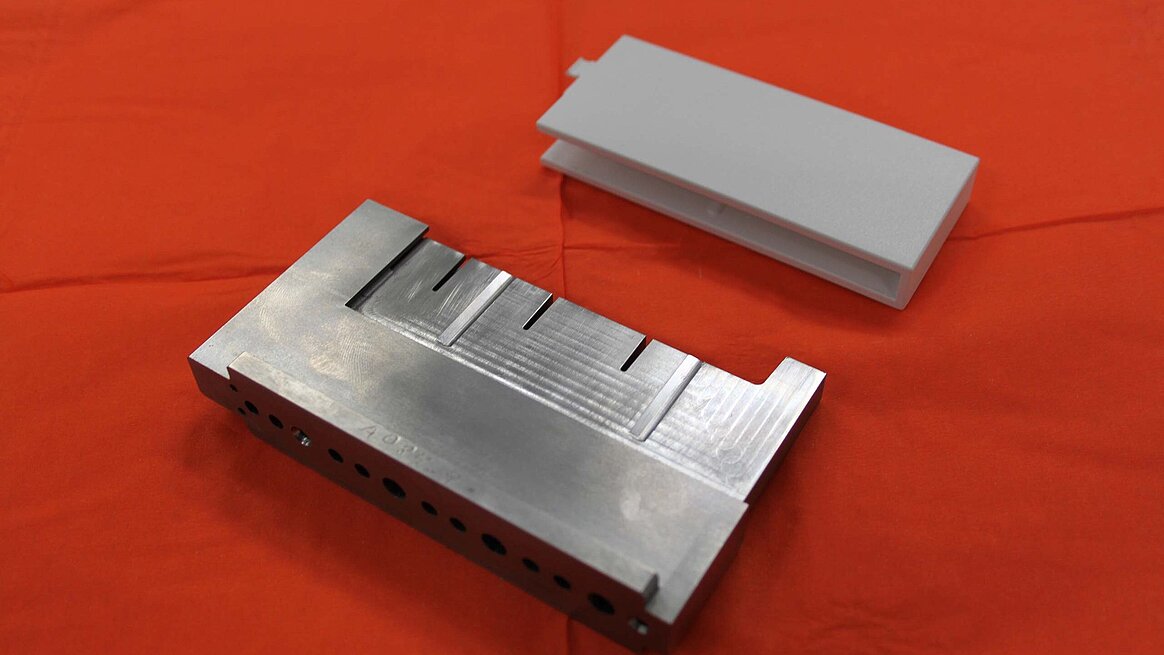

Gerhard Gorbach, Manager of Equipment Manufacturing in plant 3 of Julius Blum GmbH in Höchst, Austria, explained: "Whenever possible and practical, we use the latest technologies and processes. We approach these projects with an evaluation process on three levels. That includes a thorough record of the idea plus a feasibility check and formulation of the project. Next comes the fundamental decision for choosing the technology. Choosing the partner to accompany us on a new path completes the initial process. We always want to work together for the long term and we take an active part in development steps." This is just what happened with the new "generative manufacturing" technology, which should play an important role in the "Automated manufacturing in tool making" project we have been running for a long time. From a starting point of 5-axis complete/simultaneous machining on high-performance 5-axis CNC machining centres from long-time supplier Berthold Hermle AG, D-78559 Gosheim, and in view of the recently presented MPA technology for generative manufacturing of components for injection moulding and die cast tools and moulds, Blum made the decision to become involved. Gorbach and his colleagues believe that generative manufacturing is the next logical step towards further streamlining in manufacturing of die cast tools with cooling close to the contour or mould inserts with a CU core. Originally Blum emphasised generative manufacturing of prototypes, but it soon became evident that the advantages of MPA technology were primarily in the applications mentioned above, which probably held more than enough potential. A "cover flap" plastic part was chosen as reference project by Gerhard Gorbach and Klaus Holzer, Master Mould Maker responsible for the generative manufacturing/MPA project. This part will be required in high volume. Because of the high quality standards for functionality, precise fit and visible surfaces, it represents a challenge for the injection moulding process due to the continuous cooling.

Impressive practical test: MPA-manufactured tool cavities

Klaus Holzer explains: "Until now we had to manufacture these tools from two parts which were then soldered together. We were working with multiple injection moulding tools due to the high unit numbers, and they had to withstand an internal pressure of 1000 bar and quite high cycle frequencies for moulding the cover flaps, which were not a simple matter. So there were repeatedly signs of wear, which resulted in problems with process reliability. Because MPA technology from Hermle promised real benefits for us by using suitable, and especially homogeneously connected materials machined with high precision plus automated machining and reduced manufacturing time, we set up a practical test and equipped a 4x die cast tool for cover flaps with two conventional and two MPA-manufactured cavities. MPA-manufactured cavities are based on tool steel (1.2344). They have coolant channels close to the contour for better heat dissipation and especially for continuously controlled heat dissipation. Blum is expecting other advantages from tools manufactured using MPA technology. The quality of the injection moulding and increased productivity per time unit (due to continuously controlled cooling, which shortens cycle times) are not the only reasons why senior management at Julius Blum GmbH is very impressed with the MPA technology from Hermle.

Summary and outlook

By way of summary, Gerhard Gorbach noted: "This technology opens up a whole new series of advantages that are not necessarily apparent at first glance. In the future we can design tools for injection moulding and also for die cast parts more compactly, which means having more cavities with the same size to further boost productivity with existing injection moulding machines. The CAD data for tools and components can also be optimised for manufacturing, which further supports automation and streamlining in mould and tool manufacture. Now this type of tool is designed and manufactured as one piece instead of two, and soldering is completely eliminated as an intermediate step and in post-processing. Process reliability also increases and reproducible product quality is guaranteed. We believe another important advantage is the possibility of using an extensive range of tool making materials with widely varying characteristics together, which in turn allows us to address requirements specifically related to the injection moulding or casting process in detail. And this is without having to make any compromises whatsoever, for example in productivity, quality or surface finish, or in the associated light incidence for our externally visible products. Seen in this light, generative manufacturing in the form of Hermle's MPA technology promises much potential for Blum in the future, which we will tap together with our partner Hermle."