Entry into automation

The HS flex handling system with two pallet storage modules, each with three shelf levels and a set-up station, is connected to the machining centre in such a way that the C 400 U can work unmanned overnight. "This solution offers economical entry into automation," emphasises Andreas Härtter from Hermle + Partner Vertriebs GmbH. The operator at the machine can easily operate the handling system via the Hermle Automation-Control- System (HACS) and an integrated touch panel.

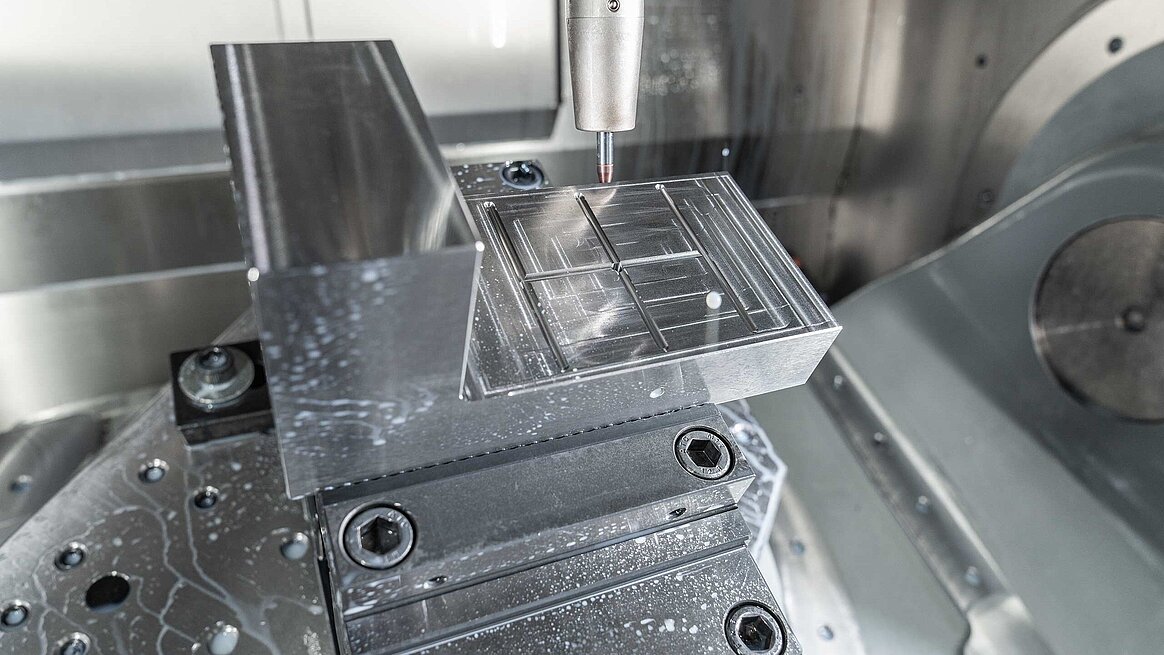

The working range of the C 400 U is 850 x 700 x 500 mm (X, Y and Z directions), the clamping surface of the swivelling rotary table measures 440 mm in diameter with an 885 mm collision circle. Thanks to the optional ZM 88k additional magazine, a total of 126 tools can be kept at the ready – sufficient for the planned fully automatic machining of the forming tools and common parts.

In addition to the automation solution, the new machining centre is very impressive due to its efficiency and quality. In the long term, Schmidt even wants to decommission an older milling centre when the C 400 U can run two shifts a day. "We are currently able to achieve this on three days a week – which after only three weeks in operation is a very satisfactory interim result," the Managing Director reports. He is certain that the target will be reached in the course of 2019 and concludes by saying: "The majority of problems currently encountered are user errors." If they lead to a crash, Schmidt is fully satisfied with the fast service: "This is a unique selling point of Hermle."