Milling and automation from a single source – this was the impetus of the Condor Group for choosing the solution from HERMLE. The RS 1 robot system supplies two C 32 U 5-axis machining centres with workpieces, turning night into day. To further maximise the effectiveness of the system, the contract manufacturer developed its own die system.

The team in the milling department works in one-shift operation. Despite this, the Condor Group with its 70 employees machines workpieces for its own products and external customers around the clock. "We rely on automation with our HERMLE system", explains Dominik Schulte. Together with his sister Ira Fecke-Schulte, he is the Managing Director of the Condor Group with headquarters in Salzkotten, close to Paderborn in North Rhine-Westphalia. The Group includes Condor Custom Solutions and Condor MedTec. Custom Solutions manufactures various parts for medical technology, toolmaking and special machine construction, electrical engineering and motor sports. In addition to milling, the catalogue of services also includes wire eroding, additive manufacturing and surface technology.

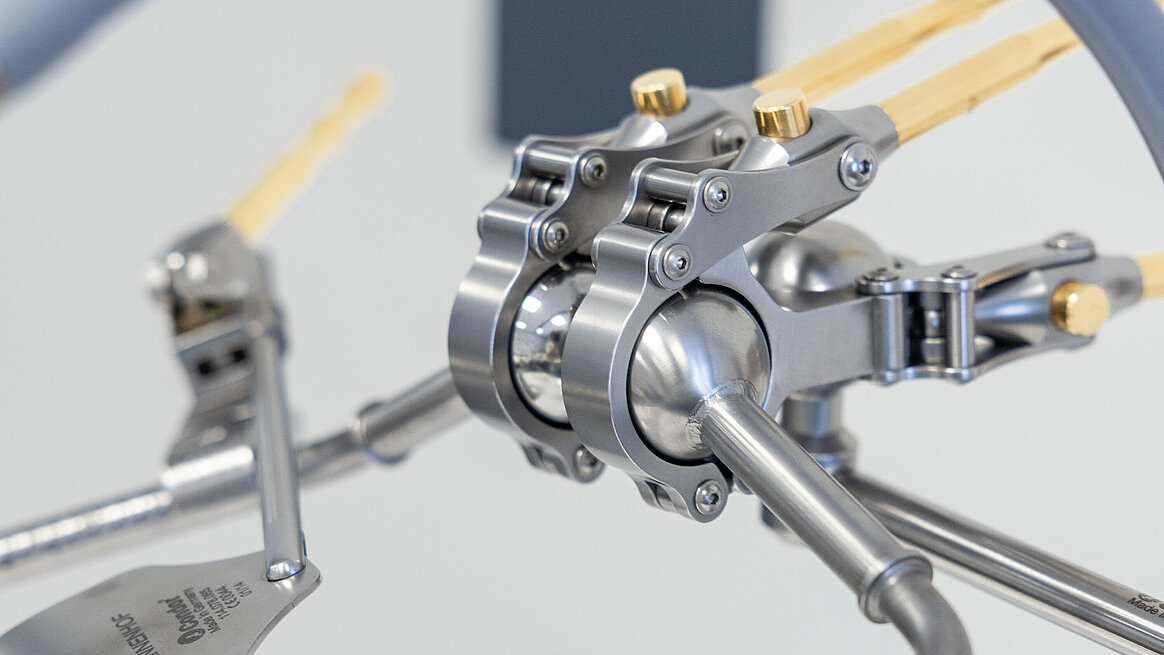

Condor MedTec develops solutions for medical technology and specialises in two categories: GoldLine is a retractor system used to keep wounds open during an operation. Without this wound retractor, one or two OP assistants would be needed to hold the skin and organs with retractors. "Hospitals need personnel for this and they are often lacking in the daily routine of a clinic", explains Operations Manager Sebastian Ilsen. The second area of specialisation is patient positioning, for example with a RotexTable. This electrically powered aid positions the patient's leg and holds it in place for hip operations.

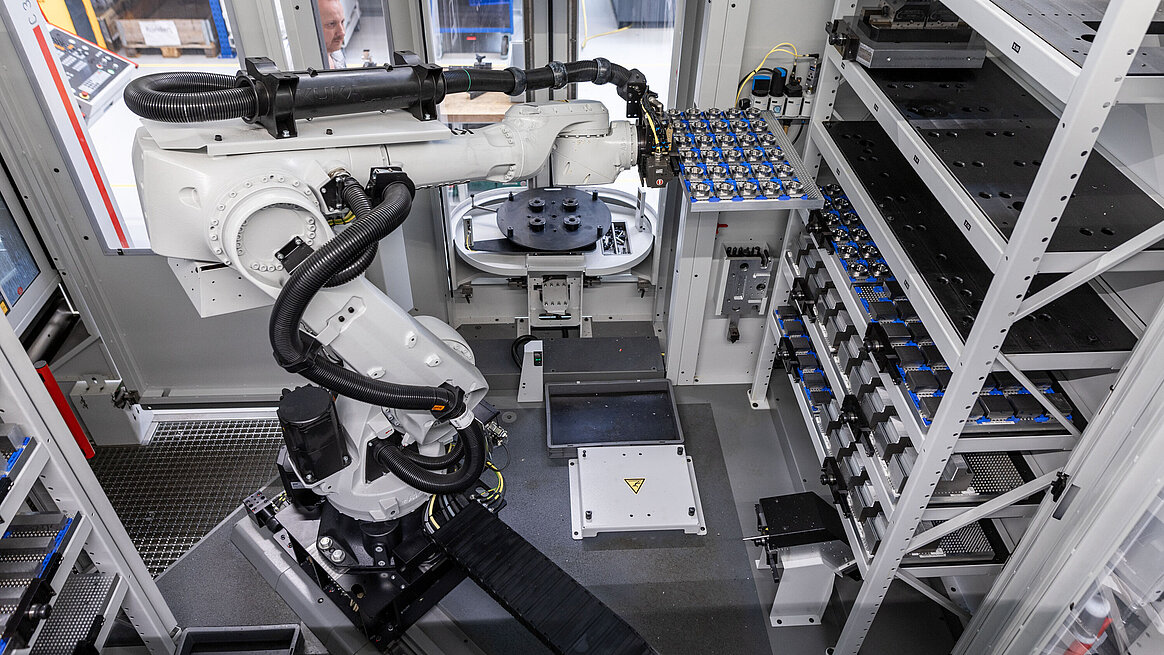

To enable automated production, Condor has been using two C 32 U 5-axis machining centres since 2022 that are connected via the RS 1 robot system. Thanks to the storage concept with two racks, which offer space for a total of 16 pallets, and fully automatic gripper changes, the HERMLE system works autonomously over long periods of time. "Not only did we double our production capacity with the two identical machines, we can also separate the material", explains Sebastian Ilsen. One C 32 U machines exclusively aluminium, the other only stainless steel. "That has several advantages", he points out. "First, in this way we can ensure that our tools always cut only one metal. In addition, this gives us chips in batches of identical materials, which are easier to recondition."

No night shifts for employees

The company chose HERMLE because of the consistent automation solution. "Due to the skilled labour shortage resulting from demographic change, it is harder for us to find employees for two or even three shifts. But we have a lot to do", emphasises Dominik Schulte. "Part of our workforce applied for a position with us because they didn't want to work any more night shifts. With the robot system we now manufacture 24/7, without stressing our personnel. We also present ourselves as an attractive employer." It was important for the company to use a machining and automation solution from a single source. "If the robot and milling centre come from different manufacturers, there can be interface problems and discrepancies in areas of responsibility", reasons Sebastian Ilsen. "We want to avoid that at all costs and therefore capitalise on a complete solution. Our employees supported us in the search. They discovered the HERMLE solution on the Internet."

After the presentation by the sales representatives, it quickly became clear for Condor that they would be manufacturing with an automated HERMLE system in the future. "We then presented the new solution to the complete milling team. In this way we were able to get the workforce on board and let them know that the robot would not cost any jobs", emphasises the Managing Director. "We employ exclusively skilled workers. They are top-notch people and we don't want to lose or replace anyone." Four employees took on the new task and were chosen for the HERMLE project team. Two programmers and two machine operators attended all the application trainings and learnt the ropes of the system. The Heidenhain TNC 640 control unit was familiar terrain, as they were already acquainted with its operation from other CNC machining equipment. The SOFLEX manufacturing control system, which controls automation thus the robot, was new for them.

Doubts dispelled

However, there were some initial reservations in the milling team. "Some employees were sceptical whether the robot would be able to cope with individual parts as well", recalls Sebastian Ilsen. Condor placed the system in operation little by little. At first only the C 32 U, then the RS 1 robot system. The second, identical C 32 U followed just a few months later. Both machining centres have an additional magazine ZM 216, which adds 216 more tools to the 36 in the machine. Condor uses three to four replacement tools for machining stainless steel. "We use a CAM system to control the machine and we are able to simulate new milling processes with it", explains Sebastian Ilsen. "The doubts were unfounded – we now produce batches of 1 as well over night, unsupervised and absolutely reliably."

"Nevertheless, it took several months until we were able to machine with the system in a one hundred percent reliable process and our employees were completely up to speed", remembers the Operations Manager. But after a short time, the project team was already considering ways to optimise processes. Once basic trust in the system and robot was achieved, everything was set to improve. The catalyst for this was the great diversity of products Condor was able to machine on the HERMLE machine.

![The RotexTable with RotexShoe holds the patient's leg in place while the retractor system holds the wound open during a hip operation.[Translate to English:] Der RotexTable mit RotexShoe fixiert das Bein des Patienten, während das Retraktorsystem die Wunde bei einer Hüft-OP offenhält.](/fileadmin/_processed_/e/7/csm_Bild16a_S9A5219_435addad7a.jpg)