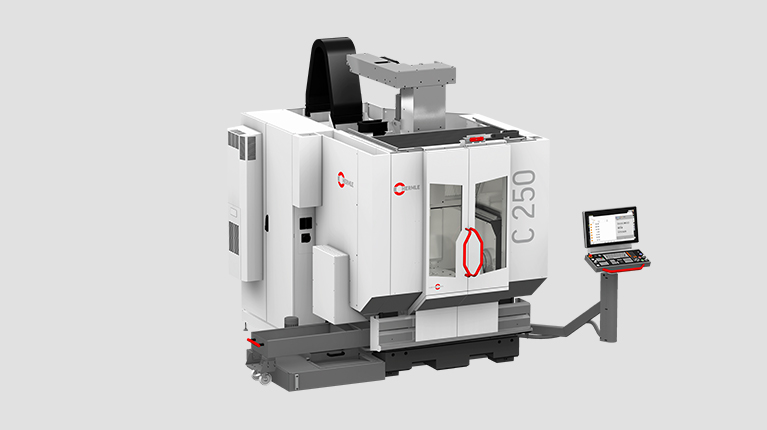

Technical Data

Dimensions

-

Störkreis: Ø 770 mm

-

Verfahrweg: 600 x 550 x 450 mm

-

Maulweite: max. 550 mm

-

Körper: Ø 450 / H 355 mm

Facts

-

Rotational speed: 15000/16000/20000 1/min

-

Rapid traverse linear X-Y-Z : 35 m/min.

-

Rigid clamping table: 800 x 616 mm

-

Max. table loading: 1100 kg

Applications

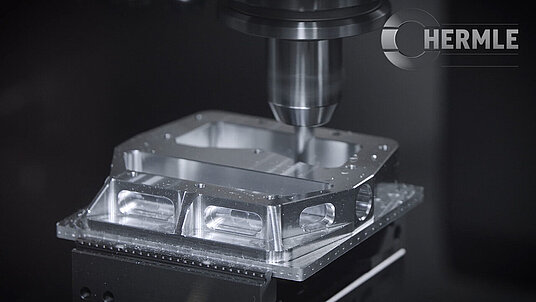

C 250 | Vehicle technology | Rocker box

HERMLE C 250 U in 5-axis version. Machining a rocker box in Toolox33 for vehicle technology

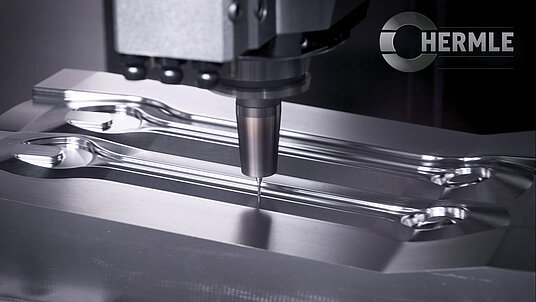

C 250 | Tool and mould making | Die mould

HERMLE C 250 in 3-axis version. Machining a forging die in 1.2767 (52 HRC) for tool and mould making

C 250 | Sports and leisure industry | Pedal for a downhill bike

HERMLE C 250 in 5-axis version. Machining a pedal for a downhill bike in AlMgSi1 for the sports and leisure industry

User reports

Dynamic for series production

HIN Feinmechanik GmbH

Prototyping

From draft to design through to production: HIN Feinmechanik has successfully established itself as a specialist in complicated components and complex devices. The "Made in Germany" quality seal is important to the owner – including in his stock of machinery: all six milling centres are supplied by Hermle in Gosheim.

Expanding capacity before reaching capacity

Kretzschmar & Siber

Contract manufacturing

"Hermle makes no distinction between large and small customers. As a rule, the service technicians are on site within 24 hours and always have a solution ready," praises Silber. The issue of competence is particularly important to him. If it is missing, there are consequences, as he sees in other companies: "Without the appropriate know-how, the best machine is of no use.