For efficient production.

Workpieces of various shapes, sizes and weights can be handled automatically by handling systems to save costs and time.

Overview of handling systems

Handling system HS flex

Available for the HERMLE machining centres C 250, C 400, C 12, C 22, C 32 and C 42 GEN2

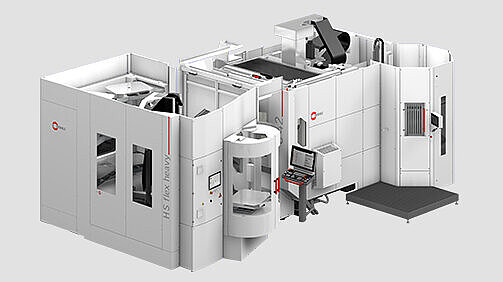

HS flex heavy handling system

Available for the HERMLE machining centres C 400, C 650, C 32 and C 42 GEN2

IH systems

Available for the HERMLE machining centres C 12, C 22, C 32 and C 42 GEN2

User reports

Discover what our customers say about us.

Update only with automation

Cafmeyer

Tool & mold making

Cafmeyer manufactures press moulds. The more complex the part, the more parts needed for the mould. In the past, the Belgian mould maker was sometimes pushed to the limits of its capabilities – both in terms of dimension and capacity. The company therefore decided to invest in a Hermle C 650 U 5-axis machining centre with HS flex heavy automation.

Ensuring efficiency and high-end quality

Dieter Wiegelmann GmbH

Plastic engineering

Injection molding

Wiegelmann is an expert in aluminium and steel mould making and plastic injection moulding. The mould maker is a stickler for deadlines and perfection, even when the parts have complex geometries. When it comes to machining, Wiegelmann relies on Hermle. HS flex automation arrived at the German company in the shape of the new C 42 U, making sure its range of machinery is even more flexible and versatile.

Know-how in both directions

Jung Werkzeugbau GmbH

Tool and mold making

Jung Werkzeugbau GmbH is expanding its mechanical production capacity: an automated C 42 U from Hermle is set to expand the company’s three-shift operation to include unmanned night-time and weekend shifts. Those responsible for paving the way are overcoming the last optimization hurdles and installing additional safety features.