What was good is about to get even better HERMLE GEN2

Your investment in the future

HERMLE is set to present the first three models of the new Generation 2 at this year’s Open House. Three models, namely the C 650, C 32 and C 42, were chosen and represent the medium machining segment due to their size and working area. Over the next 18 months, all machine models will be converted to the GEN2 architecture as part of a defined development process.

The GEN2 models have experienced minor visual adjustments, primarily to the two front panels and the machine lettering, which are now being implemented as standard across all models.

During this change process, the mechanics, which is fundamental to the precision and long-term accuracy of HERMLE products, was not altered. The key values of the machine remain exceptionally high, thereby clearly reaffirming its dominance in the field of 5-axis technology.

GEN2 is the ongoing transition towards a new machine generation of the future. Numerous software and hardware components now feature cutting-edge technology. The entire electrical architecture has been revamped to incorporate ProfiNet as the communication bus, while a significant number of the sensors have been converted to IO Link (international standard). Furthermore, the entire drive network of Heidenhain machines has been revised and equipped with the latest generation of converters. These are all components that make the machines even more efficient. The entire platform introduces new technologies and functions, including cutting-edge interface technology and evaluation/diagnostic capabilities for enhanced service analysis in case of errors.

-

C 650 GEN2 with swivelling rotary table for a load of up to 1500 kg -

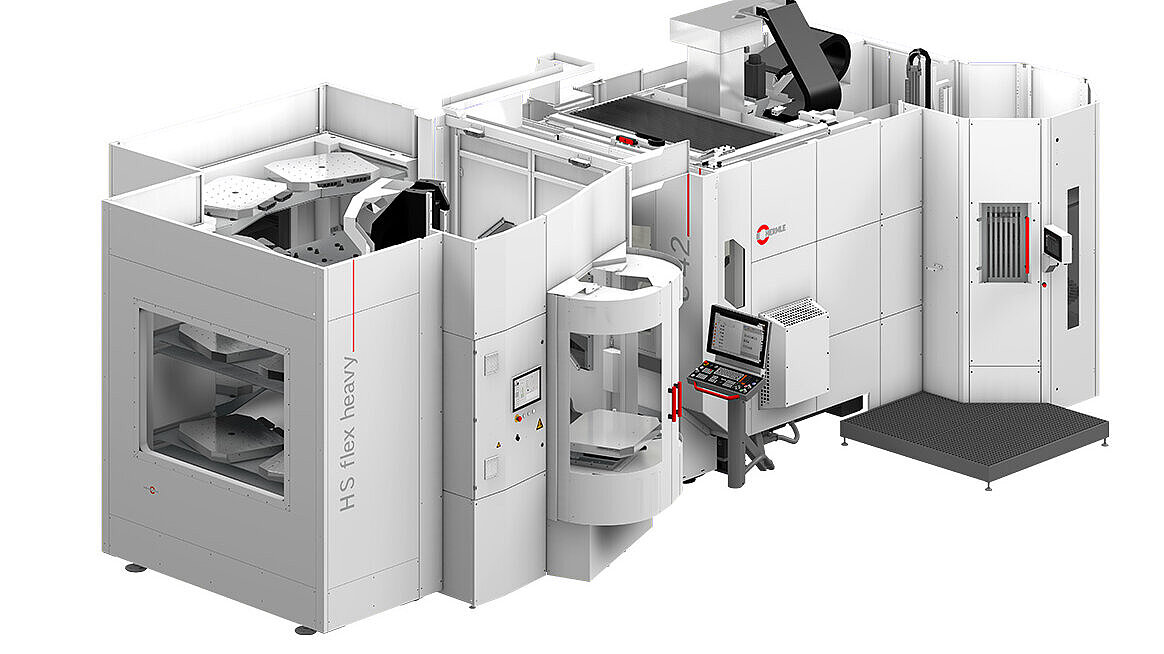

C 42 GEN2 with the HS flex heavy handling system and 2 storage modules -

Two C 42 GEN2 with RS 1 robot system

The energy efficiency of the entire machine (cooling units of the switch cabinet and spindle) has been further enhanced in combination with the high-pressure systems. In the future, many of the auxiliary units will transition to frequency-controlled drives, allowing for demand-driven and thus more energy-efficient closed-loop control. In addition to the financial benefits for our customers, this also allows us to make a real contribution to climate protection.

The entire CL management (CL = cooling lubricant) has been completely modified. This optimisation improves CL filtration, thereby enhancing its cleanliness and longevity.

In the future, GEN2 machines will be available with both Heidenhain TNC7 and Siemens Sinumerik ONE controls.

The key highlights of the HERMLE GEN2 machines include:

|

|

Compact ZM 30 additional magazine for machine models C 650, C 32 and C 42 (GEN2)

A newly designed and very compact additional magazine is now offered along with the GEN2 models. The ZM 30 additional magazine expands tool capacity by 30 tools while taking up nearly 50% less space than conventional additional magazines.

The additional magazine is simply adapted to the existing magazine loading station at the rear of the machines. It seamlessly integrates into the machine enclosure, ensuring full service accessibility despite its compact size. Commissioning is also simple and straightforward. As with all HERMLE additional magazines, the additional magazine can be equipped with an operating station (touch screen) and a tool identification instrument.

HERMLE’s convenient tool management system can be called up and operated via the operating station located on the additional magazine or the control.

78559Gosheim