The additive manufacturing technology from HERMLE is based on an approach that is just as fascinating and ingenious. Find more details about how it works and the numerous novel opportunities it provides.

Possibly to also meet all your needs and requirements?

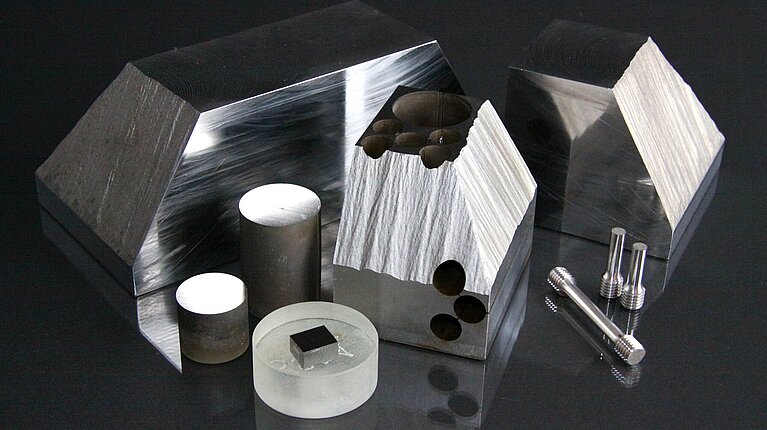

Alternating material build-up layer by layer

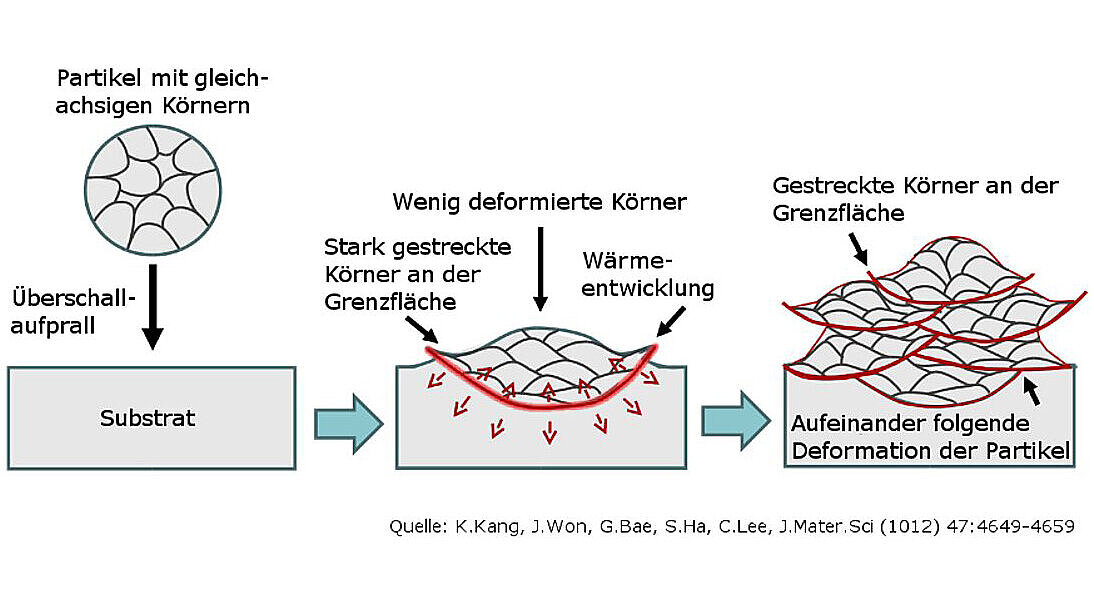

With the MPA process, the material is always applied to the surface of geometrically accessible parts of the component. If other materials are incorporated or embedded in a component, the materials are built up alternately in layers to the extent that the respective contours of the other material are accessible for machining. The contour accuracy of the component depends on the milling method and can be adapted to individual requirements. Subsequently, the other material is applied to the prepared contours and milled back into the desired shape. In this manner, a solid body consisting of two or more materials can be created.

Filling material for ducts and hollow areas

Utilisation of a special filling material enables the realisation of inner hollow areas, ducts and undercut contours. The material is water soluble and flushed out at the end of the process to expose the inner geometry. Subsequent heat treatment optimises the microstructure and ensures the component has the desired hardness.

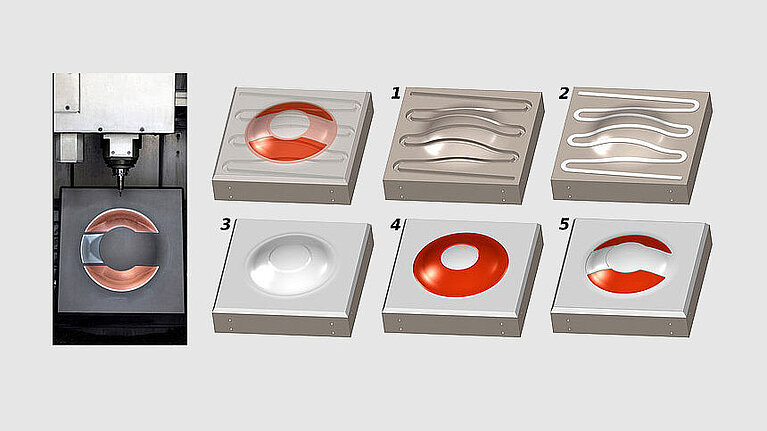

The sequence of images illustrates the main steps in the production process:

- Milling the duct into the prefabricated blank.

- Filling the milled duct with water-soluble filling material.

- Applying a top layer of 1.2344 hot-working steel. Milling the contours of the copper insert.

- Applying copper in a pre-milled contour, which is then milled back into the desired shape

- Applying another layer of 1.2344 steel. Finally, opening the view panel to the copper insert and removing any filling material still present in the duct.